Content

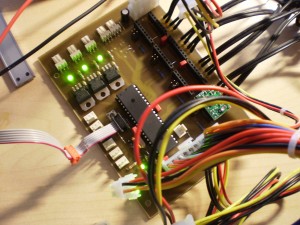

Generation 7 Electronics

This is a RepRap controller board designed to be do-it-yourselfable. Replication is what makes RepRap unique, so this is extended to controllers here. All Gen7 PCBs can be manufactured on a RepRap, on a general CNC milling machine, etched with the toner transfer method, or they can even be bought.

The circuitry design is similar to other single/stacked board solutions like RAMPS or Sanguinololu. Generation 7 Electronics can drive the same hardware. Additionally, it comes with a few nice details to make it more reliable.

- Discuss this set of electronics in the Generation 7 Electronics forum thread.

- Download files from the Generation 7 Electronics GitHub repository. All the releases are tagged.

- Find manufacturing files in the latest release files folder.

Note: Generation 7 Electronics is licensed under Creative Commons BY-NC-SA. You're free to make your copies of the hardware for personal use. If you want to purchase Gen7 components, please stick to the development supporting distribution channels. Thank you.

Features & Specifications

Highlights

- Fast: as many as 130'000 steps/second have been demostrated.

- Can drive four steppers, an extruder and a heated bed directly off the board.

- Comes with connectors for two SPI devices, e.g. SD cards, displays or even a slave controller.

- Switches the power supply on and off automatically.

- A connector for emergency-off.

- All connectors indexed, so never plug in devices the wrong way.

- Outputs allow to connect solenoids or other inductive devices.

- Designed with DIYers in mind.

- Modular: main processor and stepper drivers can be replaced without soldering.

- Easy to buy or to manufacture DIY.

Design Goals

Perfection (in design) is achieved not when there is nothing more to add, but rather when there is nothing more to take away.

Antoine de Saint-Exupéry

- Keep the replicability, i.e. minimum distance between two tracks is 0.4 mm. This mostly rules out SMD chips.

- Get independent from industry devices.

- Put emphasis on flexibility, ease of use and reliability.

- Have only essential features on the base board, put additional stuff on extension boards.

How to get it

Right now, look at the Generation 7 Electronics page.

See also the wiki pages of the individual boards.

Individual Components

As Gen7 is a single board solution, it consists of only few components:

Board-ARM

Gen7 Board is the central unit. It can drive a RepRap machine on its own, but not much more. Full power to the basics, no expensive extra features.

Latest Release: v2.0

18. February 2016

New features:

- ATmega replaced by NXP LPC1114FN28, a 32-bit ARM CPU running at 48 MHz.

- Signal voltage now 3.3 volts.

- Three jumpers for microstepping selection instead of two.

- External reset / emergency stop connector.

- Connector for always on fans (5/7/12 volts).

- Extension Board connector replaced by two SPI connectors.

- Thermistor resistors 1K/4K7 instead of 4K7/4K7 for higher accurarcy.

- MOSFET driver and voltage regulator to adjust for 3.3 V signal voltage.

- More capacitors for smoother stepper operations.

Endstop

Gen7 Endstop v1.3.1 is an optical endstop for controllers with 5 V signals (incompatible with Gen7 Board-ARM), made to fit on Mendels & Co.

Extension Boards

Extension boards are what makes Gen7 powerful and feature rich. While the base board has only the essentials to get your printer running, you can add on this part later to enjoy all the goodies.

Here are a few extensions currently in development or already working:

Gen7 ExtensionBoard USB A

ExtensionBoard USB A: USB adapter using an ATtiny45/85

Gen7 ExtensionBoard USB B

ExtensionBoard USB B: USB adapter using an MCP2200

ExtensionBoard 2E

ExtensionBoard 2E: Enhance your Gen7 with dual extrusion support.

Gen7 Multistack

Xoan shows here how to design extension boards to allow stacking multiple ones.

LDC SD FAN

Gen7 ExtensionBoard LCD SD FAN by NightFly is an extension board with all the spiffy features people like: LCD, rotary encoder, fan connector, …

LCD Display Connector

Wiring Parts

Besides the parts needed for the individual components, you need thin wires to get the thermistor and end-stop signals to the Board. For example, you can salvage the cables you find between a PC main board and the PC's hard disks or those from any fans, indicator lights and reset switches.

Heaters and stepper motors need a bit more current, so the wires should be thicker. It's a good idea to use cables from mains household appliances. These have typically 2x or 3x 0.75 mm2 (~18 AWG) wire multi conductor cables. Remove the outer insulation carefully, and then re-group them in sets of two or four, as needed; twisting the wires while doing so reduces electromagnetic influence and keeps them tidy. Label the ends if you do not have enough colours, a permanent marker can be used to add a stripe to both ends of a wire, this lets you use one colour twice (and keep pairs matched up).

For shorter links or intermediate currents, the coloured wires from salvaged PC power supplies are well suited, sometimes they have two thicknesses on one PSU, you can strip the ends and compare which ones are the most suitable, they come in a number of colours, black, red, yellow and orange are the most common.

Assembly Instructions

As the wiring of the boards is slightly different for each released version, these details have been moved to the board's page.

Notice Regarding Legal Stuff

Generation 7 Electronics isn't a device in the sense of European Community regulation 2004/108/EG (EMC Directive). The reasons include:

- Gen7 doesn't include a power supply, so a Gen7 can't be used on it's own.

- Same for the stepper drivers. No stepper drivers, no useable Gen7.

- Heaters, thermistors, ditto.

- The instructions seen on the Gen7 wiki pages give you hints on how to build your own device, they're not to be seen as installation instructions or a manual of a finished device.

If you use a Gen7 to assemble something usable, check (at least) the following if you want to conform to said regulation:

- Is there a metal housing? A Faraday Cage solves most electromagnetic issues.

- Connected cables can also be subject to electromagnetic stuff. Shielding them helps.

- Is there a manual and are there installation instructions conforming to the regulation?

If you buy and assemble an Generation 7 Electronics kit, you're manufacturer in the sense of the EMC Directive, not an end user. As long as you're developing and testing, most EMC regulations don't apply (for obvious reasons). The directive just wants you to protect devices of third parties from yours, so don't run a Gen7 right next to your neighbour's cardiac pacemaker. There's no time limit for developing and testing.

That said, this section mostly applies to all currently known RepRap electronics. Also, the said was written after investigation of relevant law texts by an mechanical engineer, not a lawyer.

Relevant law: EMVG, implementing the EC directive for Germany.

History

The Forum thread (german), where everything started.

Work Around Christmas 2010

Mostly done by Jacky2k.

24.12.2010: A first version of the Gen7 board has been etched and is being tested. The hardware seems to work, but the software still needs to be ported and tested with a RepRap.

29.12.2010: Some patches were made in the firmware to support endstops and homing. The patched firmware can be downloaded in the firmware section.

30.12.2010: Some more patches to the firmware. Current firmware seems to be stable and working. Not 100% tested yet.

04.01.2011: We found some bugs in the firmware again. All of them seems to be fixed, release is planned tomorrow.

05.01.2011: Uploaded current firmware with a lot of patches.

08.01.2011: Some little modifications of the PCB are required. Pull-up resistors for I²C are missing, we want to change some headers to more common one, some resistor values are missing, …

09.02.2011: The master branch of FiveD on Arduino firmware is ported and seems to work but is not tested 100%. The config file for the firmware will come soon.

March 2011: Four Mendels are driven by Gen7 Electronics successfully, first reprap'd PCBs were shipped.

Older Releases

10. Feb 2011: v1.0

New features: it works. Isn't that the most important thing on an 1.0 release?

28. Mar 2011: v1.1

New features: fix all those silly 1.0 mistakes.

- Cleaned up that drill size mess. Now 275 of the 369 holes are either 0.75 mm or 1.0 mm, the remaining ones are the bigger ones for the connectors and can be drill-milled.

- Various smaller changes for better compatibility with G-Code generators.

- Added an appropriate plus (+) signs to all polar components.

- Swapped the TIP120 MOSFETs for IRFZ 44N ones. These are now fast enough to allow PWM in the kHz range.

- Added two jumper headers to one existing to have one for each of the three possible power sources. This adds safety against misconfigurations: use only one jumper and you're always safe.

- Fixed the solder mask.

- Changed the pin assignments of the heater MOSFETs. Now they're on PWM-able ATmega pins.

- Added a Release Maker script, bundling up design files for those without gEDA.

- Added Arduino Support, consisting of bootloaders, board descriptions and library files.

12. May 2011: v1.2

New Features:

- The endstop now uses the TCST1103/2103 photo interrupter.

22. July 2011: 1.3

New features:

- Supported EDA toolchain is now gEDA 20100929, the one coming with Ubuntu 11.04.

- Use stronger 2 pin, 4 mm connectors (same type as the motors) for the heaters. These match the required current much better.

- Remove the MOSFET for the fan. Only few people use a fan. If you're one of them, connect the fan to the PSU directly.

- Remove the I2C header. Was totally unused.

- Make thermistor connectors 2 pin only. The extra pin just caused confusion.

- Replace the ATX20 with an ATX24. The new header is compatible with more recent PC power supply types and accepts ATX20 plugs just fine.

- Use another disk power type connector to supply the heaters. This allows to run a heated bed directly off the Gen7 board, without relays in between. This also introduces the ability to use different voltages for motors and heaters, without making things more complex for casual users.

- MOSFETs are now upright, for better cooling and mounting a heatsink. Also inserted a matching heatsink to the parts list.

16. August 2011: 1.3.1

This is a bugfix release.

- Attempt to prevent bootloader corruption by turning on the Brown Out Detector.

- Make the bootloader itself a bit shorter.

- No changes to the hardware.

15. May 2012: Gen7Board v1.4

New features:

- Most important: Gen7 features now an extension header, so you can stack a feature-rich board on top of the base board. This shall allow for SD card support, additional extruders, displays and perhaps even multi-color extruders.

- Changed motor headers from KK156 to KK100 ones. KK156 are Gen3 and screw terminal compatible, KK100 are RAMPS/Sanguinololu/Gen6 compatible. The later are significantly cheaper and a lot more in use these days.

- Reduced the number of endstops to 3, so endstops no longer share pins with the ISP header. Additional endstops can go onto the extension board.

- Connect the thermistor to 5V Standby. This allows to read temperatures without turning the power supply on and requires just 0.1 mA additional juice at room temperature, so the additional energy needed for running the thing 24/7 is neglibile.

- Better GND routing for even more accurate temperature readings.

- Reduce resistors between ATmega and MOSFETs to 10 Ohms to allow for higher PWM frequencies.

- Tested support for the ATmega1284P.

August 2012: Gen7BR2

Diego Soares tweaked the Generation 7 electronics design, swapping out some of the connectors and other parts for parts that are easier to find in Brazil, producing the Gen7BR.

RepRapBR - Grupo de Estudo: "Placa para RepRap Gen7BR2 - nacional"

(RepRapBR - Study Group: “Board for RepRap Gen7BR2 - National”)

17. August 2012: Gen7Board v1.4.1

New features:

- Distinction between extruder and bed circuitry (heater MOSFET, thermistor connection) to allow differences between them.

- Better MOSFET for the heated bed, bringing in more robustness and making MOSFET heatsinks obsolete.

20. December 2012: Gen7 Board-AVR 1.5

New features:

- The USB adapter is now on the main board. Pretty much what's on the ExtentionBoard-USB-B already, making this obsolete.

- Noise canceling coil for AVcc now 10 uH. This makes Gen7 compatible with firmwares supporting LCD displays. Previously, hooking up a display would trigger the brown-out-detector often.