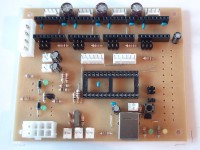

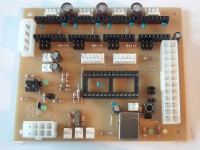

Gen7 Board-ARM 2.0 Assembly

This page is about how to solder a Gen7 Board-ARM v2.0. Everything lying around, in bags or single parts? Fine. Let's heat up the soldering iron.

General Notes on Assembly

- Especially as a beginner, prefer leaded solder. Much easier to handle.

- No expensive iron needed, but it should have a (simple) temperature regulation. Unregulated irons overheat, too much heat makes the solder flux vapouring away too quickly, leading to bad solder joints.

- A solder sucker is cheap and well invested money.

- To find out which components to put where, have the layout on your PC screen available.

- PCBs fabricated with Voronoi paths need more heat, so raise your soldering iron's temperature by about 20 deg Celsius.

- When soldering parts with many pins, like the ATmega socket, it's good practice to start with the four corner pins, recheck the fit, then soldering every other pin first, before completing the remaining ones. This keeps heat and strain to a minimum.

- Start with the flattest parts, usually wire bridges or resistors. This way, components won't fall out when you lay the PCB on it's front for soldering. Then continue with parts of raising height.

- The parts lists are sorted with that in mind, simply start at the top and assemble towards the bottom.

- To ease soldering parts which fall out easily anyways, a small drop of glue onto the component side before inserting them helps.

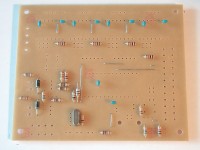

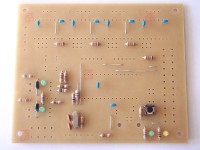

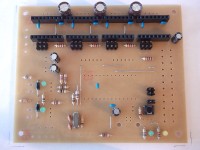

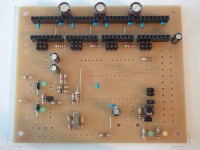

Assembly in Detail

Caution: Don't solder MOSFETs or insert the LPC1114 until after the Voltage Measurements.

Click on the pictures to view them larger.

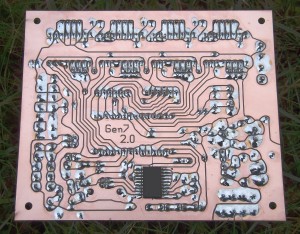

![This is the layout, seen from the component side. If you're unsure, always refer to this picture of the layout. The designators match those in the [[Gen7 Board-ARM 2.0#Parts Lists|parts list]]. This is the layout, seen from the component side. If you're unsure, always refer to this picture of the layout. The designators match those in the [[Gen7 Board-ARM 2.0#Parts Lists|parts list]].](https://www.reprap-diy.com/_media/gen7/gen7_2.0_layout.png?w=200&tok=c30567)

This is the layout, seen from the component side. If you're unsure, always refer to this picture of the layout. The designators match those in the parts list. | ||

|

||

Tadaa! You're done with soldering. Well, almost :-)

Now you can continue with Voltage Measurements, it's a good idea to insert sensible parts only after that.

gen7_board-arm_2.0_assembly.txt · Last modified: 2018/05/27 16:10 (external edit)